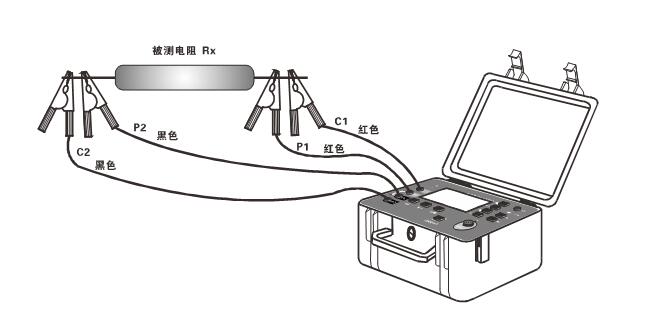

ES3050 equipotential tester parameters introduction

Function: equipotential bonding resistance test of metal components, low value resistance test, resistance test of connecting conductor between ground grids, contact resistance test, etc.

DC resistance: 0.0001Ω~30.00KΩ

Resistance resolution: 0.0001Ω

Test current: ≥1A

AC voltage: 0.0V ~ 750V AC

USB interface: with USB interface

Purchase hotline

Landline: 020-37313925

Mobile: 18818841403

QQ: 3046427731

E-mail: 3046427731@qq.com

Take a look at the examples of lightning protection grounding and equipotential installation quality problems collected by well-known housing enterprises in the project quality inspection, and interpret them in accordance with national regulations and atlases and quality requirements. The analysis of the causes of these typical problems and the treatment measures are worth learning!

ES3050 equipotential tester four-wire test wiring diagram

1. Equipotential grounding bar material and specifications are unqualified

Problem

1 The grounding row of the partial equipotential terminal box of the bathroom is made of galvanized iron sheet with a size of 10×1.3mm.

2 There is no ground flat steel.

Cause Analysis

1 The construction unit did not carefully review the construction drawings and was not familiar with the construction atlas.

2 The engineering department and the supervisor did not inspect the construction materials, resulting in more grounding materials and unqualified specifications.

3 Construction units cut corners.

4 The cost department is unreasonable for the price-sensitive materials to be used for the price of the package.

Treatment measure or method

1 The engineering department and the supervisor must carefully check the materials entering the site and the materials already installed on site.

2 For the grounding row of the equipotential terminal box that is not qualified, it must be replaced and penalized. At the same time, the supervisory inspection and supervision is weak, and the consequences of rework must be punished.

3 The engineering department is sensitive to the market changes and should actively coordinate with the cost department to adjust the pricing, avoid waiting for the cost increase, shoddy and affect the quality.

4 Construction large sample map and national standard atlas 03D501 clearly require that the grounding row must use 4mm thick copper row, construction must be replaced as required.

2.The equipotential grounding connection does not meet the specification requirements.

Problem

1 The local equipotential of the bathroom is not connected to the floor steel mesh according to the design large sample and specification requirements.

2 welding quality is poor.

Cause Analysis

1 The engineering department, supervision and construction unit did not carefully review the drawings, and did not have familiarity with the atlas and acceptance criteria.

2 The engineering department and the supervisor did not perform the inspection and acceptance of the on-site process quality, and did not promptly supervise the implementation of the rectification.

3 The construction technology of the construction unit is not in place and blind construction.

Treatment measure or method

1 The engineering department and the supervisor must carefully review and familiarize with the national standard 03D502 atlas and acceptance criteria, strengthen the inspection of the on-site process construction and the acceptance of the process quality, and promptly supervise and rectify the problems.

2 The construction unit should be familiar with the drawings, and strictly follow the specifications, national standards or local standards for the construction of the atlas, and must not be blindly constructed.

3 The partial equipotential grounding flat steel of the bathroom shall be welded to the floor steel mesh, and the welding shall be full, and the length of the weld shall meet at least the acceptance criteria.

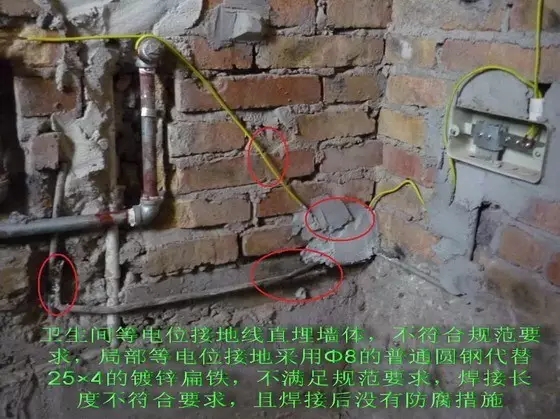

3. The connection and laying of the local equipotential grounding wire of the bathroom do not meet the requirements of the specification.

Problem

1 The equipotential grounding wire of the bathroom is connected to the metal water supply pipe without using a special grounding clamp, but is directly tied to the metal pipe, and there is no bismuth tin before the multiple grounding wires are connected.

2 The grounding wire is not laid with a protective tube and is directly laid in the wall.

Cause Analysis

1 The engineering department and the supervisor failed to check the inspection and acceptance of the concealed project, and found that the problem did not urge the rectification and the second acceptance.

2 The construction unit has poor quality awareness, no self-inspection, cut corners, and brutal construction.

Treatment measure or method

1 The engineering department and the supervisor must check and accept the concealed works. It is strictly forbidden to enter the next process without passing the inspection.

2 All rework must be carried out, and the construction unit must pass the self-inspection before the concealed project is submitted for inspection.

3 In strict accordance with the design and specifications, do a good grounding connection, set a flame-retardant wire tube, multi-strand PE line requires tin-tin.

4 If this problem is found, it is necessary to impose economic penalties on the supervision unit and the construction unit.

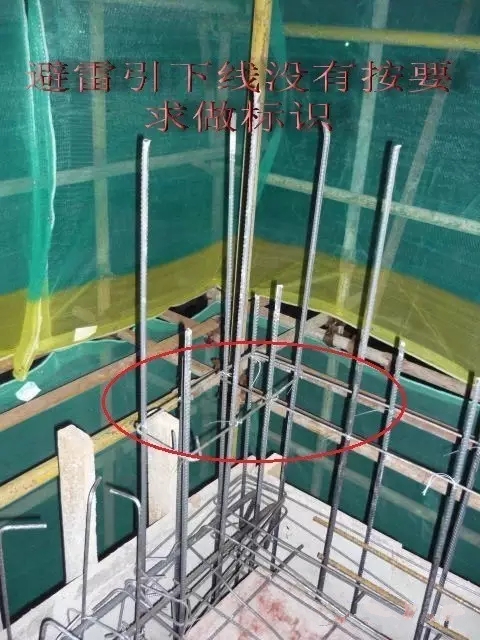

4, lightning protection grounding lead line is not marked

Problem

The lightning protection grounding lead line construction process has not been clearly marked

Cause Analysis

1 The engineering department and the supervisor did not seriously check and accept the construction process of the lightning protection grounding lead line on each floor, when the problem was discovered, the rectification was not corrected and implemented in time.

2 The construction unit has poor quality awareness, greedy convenience, and saves money on painting.

Treatment measure or method

1 The engineering department and the supervisor should check the construction drawing and clarify the position and quantity of the down conductor. In the construction process of each floor, the paint on the down conductor must be marked clearly. Before concealing, the inspection should be done, and the hidden inspection data should be checked.

2 When the diameter of the main rib of each down conductor is greater than or equal to 16, it should be connected 2 main ribs, when less than 16 it should be connected with 4 main ribs, and the connection is reliable.

5, local equipotential grounding trunk, serial laying has potential safety hazards

Problem

Series laying of the local equipotential grounding trunk exist safety hazards, which violates specifications and design requirements.。

Cause Analysis

1 The engineering department, supervision and construction unit did not carefully review the drawings and did not familiar with the acceptance specifications.

2 The inspection and acceptance of concealed works at the engineering department and the supervision site were not in place, and the problems were not promptly supervised to implement the rectification.

3 construction unit has poor safety awareness, greedy convenience, blind construction。

Treatment measure or method

1 The engineering department, supervision and construction unit should carefully review the drawings, especially the large-scale drawings of the construction drawings, and familiar with the construction acceptance specifications.

2 The engineering department and the supervisor should carefully check and accept the concealed works in accordance with the requirements of the design and acceptance specifications, and promptly supervise the implementation of the rectification.

3 The hydropower installation team and the civil construction team should work closely together and the construction should be tracked at any time.

4 Remove all equipotential grounding trunks, if it is not possible to connect with the main ribs, the grounding pole should be used nearby. Similar rework can not be charged separately.

6、Lightning protection solder joints are exposed on the roof slab structural layer

Problem

The welding points connecting the lightning protection belt and the lightning receptor are exposed on the roof slab structural layer, and the exposed parts are not treated with anti-corrosion treatment.

Cause Analysis

1 The engineering department, supervision and construction unit are not familiar with the acceptance specification and the lightning protection grounding standard atlas.

2 The engineering department and the supervisor did not conscientiously do a good job in the acceptance of the concealed project, and failed to implement the rectification of the quality supervision of the construction process.

3 The construction unit has poor quality awareness and the construction technology is not in place.

Treatment measure or method

1 The engineering department and the supervisor strengthen the quality inspection of the construction process, and strictly follow the design and acceptance specifications and the standard atlas requirements for the acceptance of concealed works.

2 The welding parts outside the structural layer should be treated with anti-corrosion treatment. At the same time, non-galvanized steel should not be used as the grounding down conductor in the future construction. The structural layer should be set as far as possible in the grounding welding. If the conditions are limited, anti-corrosion measures must be taken.

7、There are no lightning protection facilities and down conductors for roof structures

Problem

Structures with elevations above the slope roof (such as the illustrated pavilion and flue) do not have lightning protection down conductors and lightning protection facilities。

Cause analysis

1Electrical designers did not carefully review the civil construction drawings, did not review the top elevation of the roof structures, and the lightning protection facilities were leaked.

2 The engineering department, supervision and construction unit did not carefully review the construction drawings, and found that the problems were not timely contacted with the design to change.

3 Engineering Department and Supervisor did not check the construction process and the concealed project was not acceptance checked, and the problem was not promptly supervised to implement the rectification.

4 The construction unit has poor quality awareness and blindly works according to the map.

Treatment measure or method

1 Electrical design work should carefully review the civil engineering design elevation. For structures above the slope roof (such as exhaust ducts, molding pavilions, etc.), lightning protection devices should be installed in strict accordance with the lightning protection design specifications.

2 The engineering department, supervision and construction unit should carefully review the construction drawings and find out the problems in time to contact the design for modification.

3 The engineering department and the supervisor should do a close inspection and acceptance in strict accordance with the drawings and specifications, and promptly supervise the implementation of the rectification

4 Do not damage the structure, make up the lightning protection device, and pay attention to the appearance.

8、The lightning protection belt is free to climb on the facade

Problem

1 The roof lightning protection belt is suspended between the floors of different elevations.

2 destroy the overall beauty of the building

Cause analysis

1 The electrical design work did not seriously review the civil design elevation. The change of the position of the slope roof of different elevations was not clearly defined in the plan.

2 The engineering department, supervision and construction unit did not seriously review the drawings, and found that the problems were not submitted in time for design revision.

3 The inspection and acceptance of the construction process by the engineering department and the supervisor are not in place.

4 The construction unit did not construct according to the requirements of design and acceptance specifications.

Treatment measure or method

1 Electrical design work should carefully review the civil design elevation, and the change of the position of the downhill line for different elevations should be clearly defined in the plan.

2 The engineering department, supervision and construction unit should carefully review the drawings and find the problems and submit the design revisions in time.

3 The engineering department and the supervisor must inspect the construction process and strictly check the concealed works according to the design and acceptance specifications.

4 The hydropower installation team should understand the civil construction plan, prepare the materials adequately, and closely cooperate with the civil construction.

9、Lightning protection grounding flat steel specifications do not meet design and specification requirements

Problem

The lightning protection grounding galvanized flat steel is measured to be 19.5×2.2mm, which does not meet the specifications and design requirements.

Cause analysis

1 The engineering department, supervision and construction unit did not seriously review the drawings.

2 The construction materials were not tested for entry. During the construction process, there was no actual measurement of the grounded flat steel during the concealed acceptance. The problems were not promptly supervised to implement the rectification.

3 Construction units cut corners.

Treatment measure or method

1 The engineering department, supervision and construction unit should carefully review the drawings and be familiar with the materials and specifications of each construction site.

2 The engineering department and the supervisor shall conduct the material entry inspection in strict accordance with the material materials and specifications required by the design. If there is a brand requirement, each batch of material brand should be inspected strictly according to the brand requirements. During the construction process, especially the use of materials in concealed works is measured, and problems are promptly supervised to implement rectification.

3 The specification requires that the grounding main line should at least require 40×4mm hot-dip galvanized flat steel, all the unqualified materials are required to be replaced, and the construction unit and the supervision unit are subject to economic penalties.

10、Grounding flat steel welding length does not meet the specification requirements

Problem

The grounding flat steel welding length does not meet the requirements of the specification, and there is no bridging.

Cause analysis

1 The engineering department, supervision and construction unit are not familiar with the drawings and specifications.

2 Construction technology is not in place.

3 The engineering department and the supervisor did not check the acceptance of the construction process.

4 The construction unit self-inspection is not in place.

5 Construction units feel free to construct.

Treatment measure or method

1 The engineering department, supervision and construction unit should be familiar with the relevant requirements of drawings and specifications.

2 The construction unit earnestly completed the third level of construction technology.

3 The engineering department and the supervisor must check and accept every part of the project site and each process. In particular, some key parts should be carefully inspected and accepted, and problems should be promptly supervised to implement the rectification.

4 The construction unit strengthens the self-inspection. Every part and every procedure on the site must be self-inspected and submitted to the supervision and engineering department for acceptance.

5The galvanized round steel is used for bridging, or the galvanized flat steel is finished. The welding length is 6 times round steel diameter for double-sided welding and 12 times round steel diameter for single-sided welding.

11、The local equipotential of the bathroom is not grounded flat steel

Problem

The local equipotential of the bathroom is not grounded flat steel.

Cause analysis

1 The engineering department and the supervision site did not seriously check, and the concealed project acceptance was not in place.

2 The civil engineering team of the construction unit did not track the connection when the wall was built. Especially before the wall was brushed, the flat steel was not taken out and laid in place.

3 Construction units cut corners.

Treatment measure or method

1 The construction unit will weld the grounded flat steel strictly according to the design requirements during the grounding welding construction process.

2 The engineering department and the supervisor must make the concealed project acceptance on time, and timely repair the flat steel for the leaked ground.

3 The hydropower installation team should closely cooperate with the civil works when constructing the civil engineering wall. The hydropower team sent people to track in place, promptly pull out the grounding flat steel and lead it to the local equipotential terminal box to avoid the subsequent search for grounded flat steel to destroy the wall structure and waste construction costs.

12、Lightning protection grounding welding quality defect

Problem

1 The down conductor, the equalizing ring and the lightning protection belt have defects such as slag inclusion, welding, virtual welding, biting meat, and insufficient weld seam.

2 The welding slag does not knock off, and the welding place on the lightning protection belt does not brush the anti-rust paint.

3 Rebar is used instead of round steel for reinforced steel.

Cause analysis

1 The construction unit has poor quality awareness and cut corners.

2 The engineering department and the supervisor did not check the entry materials of the construction unit, and the materials preparation of the construction unit was not in place. If the construction conditions were not met, the construction was not prevented.

Treatment measure or method

1 Strengthen the skills training for welders, requiring that the welds at the lap weld be full and even,

In particular, it is training on difficult welding such as vertical welding and overhead welding.

2 The engineering department and the supervisor should strengthen the inspection and supervision of the rectification efforts. In particular, it is necessary to inspect the construction conditions such as the material preparation of the construction unit, promptly supervise the repair welding of the unqualified welds, remove the welding slag, and brush the two antirust paints.

3 Strictly in accordance with the provisions of GB50169-2002 "Code for Construction and Acceptance of Grounding Devices for Installation of Electrical Installations". The length of the lightning protection down conductor is 12 times the diameter of the round steel. Rebar should not be used instead of the round steel connection. Once found, all rework must be carried out, and the supervision unit and the construction unit should be punished economically.

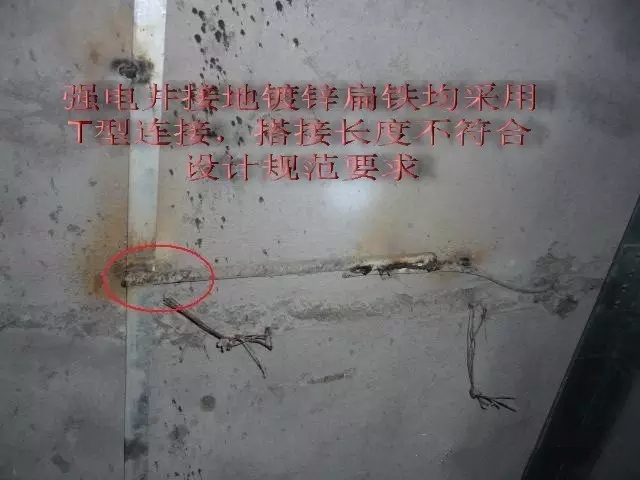

13、Grounding flat steel welding of strong electric hoistway

Problem

The grounding flat iron adopts "T" type welding, the overlapping length is not enough, the welding joint is slag, bitten, not welded, and the anticorrosion is not done.

Cause analysis

1 The on-site inspection of the engineering department and the supervision was not in place, and the rectification was not promptly supervised.

2 The quality awareness of the construction unit is poor, the technical disclosure is not in place, and there is no self-inspection.

Treatment measure or method

1 The engineering department and the supervision site shall be inspected and accepted in strict accordance with the design and specification requirements, and the problems shall be promptly supervised to implement the rectification.

2 The construction unit carefully organized the construction of the third-level construction technology and strengthened its inspection intensity and intensity.

3 Flat steel and flat steel are doubled to the width of flat steel, not less than three sides of welding, round steel and round steel overlap is 6 times the diameter of round steel, double-sided welding. The round steel and the flat steel are lapped six times the diameter of the round steel, and the double-sided welding is performed. Flat steel and steel pipe, flat steel and angle steel welding, close to the outer side of the angle steel, or close to the surface of the 3/4 steel pipe, welding on the upper and lower sides, in addition to the welded joints in the concrete, brush the anti-rust paint twice。

14、There is no local equipotential in the bathroom

Problem

There is no local equipotential in the bathroom.

Cause analysis

1 The engineering department, supervision and construction unit did not carefully review the drawings.

2 The acceptance of the engineering department and the supervision concealed project is not in place.

3 The construction unit did not have self-inspection, and the coordination between the hydropower installation team and the civil construction team was not in place.

Treatment measure or method

1 The engineering department, supervision and construction unit should carefully review the drawings and be familiar with the relevant technical requirements of the construction acceptance specifications.

2 The engineering department and the supervisor must inspect and accept the concealed project in strict accordance with the design and specification requirements. Only after acceptance is accepted, the next process can be carried out.

3 The hydropower installation team should cooperate closely with the civil construction team to strengthen their own quality inspections, strictly follow the construction drawings and specifications, and must not violate the regulations.

4 The project must be reworked, and the equipotential device of the bathroom bureau is installed according to the design requirements (The terminal plate is connected with the equipotential bonding trunk. The steel mesh in the ground should be connected with the equipotential bonding line. When the wall is a concrete wall, the steel bars in the wall should also be connected to the equipotential bonding line. The metal floor drain and the down pipe in the bathroom are connected to the local equipotential terminal board through the equipotential bonding line. When connecting, the surface of the hoop and the pipe should be wiped clean. After installation, apply protective paint. The inner diameter of the hoop is equal to the outer diameter of the pipe, and the size of the hoop is determined by the diameter of the pipe. The equipotential bonding line is laid in the plastic tube wall with BV-4mm2 copper wire).。

15、Ground wire is replaced by phase line

Problem

1 The bathroom board equipotential box connection line is replaced by the phase line.

2 The terminal block uses an iron plate instead of a copper plate and is rusted.

Cause analysis

1 The engineering department, supervision and construction unit did not carefully review the construction drawings and were not familiar with the construction acceptance specifications.

2 The engineering department and the supervisor did not seriously check the quality of the on-site project and urged the rectification to be ineffective.

3 Construction units cut corners.

Treatment measure or method

1 The engineering department, supervision and construction unit should carefully review the construction drawings.

2 The engineering department and the supervisor should carefully check the quality of the on-site project and promptly supervise the rectification of the problem.

3 The construction unit shall strictly follow the design requirements and specifications of the drawings. The equipotential bonding line shall be made of yellow and green copper conductors. The equipotential bonding terminal board shall be made of copper material, and its thickness shall not be less than 4mm2.

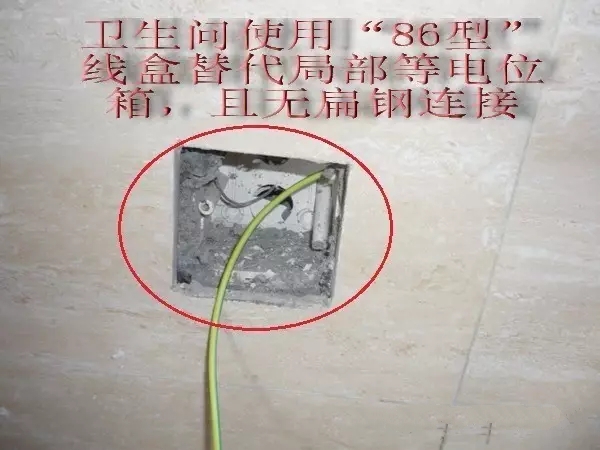

16、The equipotential terminal box is replaced by a type 86 wiring box

Problem

1 The local equipotential bonding line and the terminal board overlap surface are not tinned.

2 The terminal block is not made of copper material, but is made of iron plate.

3 Replace the equipotential special box with the '86 type' wire box.

Cause analysis

1 The engineering department, supervision and construction unit did not seriously familiar with the large-scale drawing of the potential construction of the bathroom.

2 The construction technology of the construction unit is not in place, and cut corners.

3 The engineering department and the supervisor did not carefully test the materials.

Treatment measure or method

1 The engineering department, supervision and construction unit are not familiar with the construction drawings, especially the design of large samples.

2 The construction unit should carefully organize the construction of the third-level construction technology, especially the attention of the team leader and the on-site construction personnel.

3 The construction unit shall purchase and use the materials in strict accordance with the design and specification requirements. Once the phenomenon of cutting corners is found, the construction and supervision units shall be given a heavier punishment.

4 This project should be reworked. The multi-strand wire should be crimped and then crimped. The finished terminal box should be purchased. The terminal plate should be made of copper plate, and its thickness should not be less than 4mm2.

17、Roof lightning rod setting is not standardized

Problem

1 The roof lightning rod is not standardized, and the round rod is used instead of the special lightning rod.

2 The overall effect of the villa mansion was destroyed.

Cause analysis

1 The engineering department's property quality awareness is poor, the engineering department, supervision and construction unit did not seriously review the map, and did not seriously review the installation height of the lightning rod.

2 The construction unit has poor quality awareness and the construction technology is not in place.

3 The engineering department and the supervisor did not seriously check during the construction process, and found that the problem was not stopped and urged to be rectified in time.

Treatment measure or method

1 The engineering department, supervision and construction unit should be familiar with the construction drawings and the lightning protection grounding installation atlas, and carefully review the material and design and installation height requirements of the lightning rod.

2 The engineering department and the supervisor shall carefully check and accept the construction during the construction process, and promptly supervise and rectify the problems.

3 The construction unit should carefully organize the construction of the third-level construction technology, especially the attention of the team leader and the on-site construction personnel.

4 The construction unit shall install the lightning rod in strict accordance with the design, specification and atlas requirements. The galvanized round steel shall not be used instead of the lightning rod. A special lightning rod lightning receptor shall be purchased. The installation height of the lightning rod shall be 30cm for the roof playing scene, and the self-inspection shall be done carefully.

上一篇:The specified value of the grounding resistance value of var

下一篇:没有了